We are furious farmworkers. This text is the third inquiry from our forthcoming book: Farmworker fury – Inquiries about organic agriculture. More chapters will follow soon. If you haven’t read them already, check out chapter one and chapter two! AngryWorkers also suggest reading this new article by our friend Emiliano on conditions of migrant workers on UK farms.

In 2020, we read Class Power on Zero Hours by the AngryWorkers. It left us buzzing. After some time of not knowing what to do with our inspiration, we decided to write this book about our work experiences. Leftists often either romanticize (organic) agriculture, or they want it to be fully automated and industrialised. Beyond capitalism, we will have to learn to work the land in a truly sustainable way. Therefore, we think it’s important to have a workers-based analysis of (organic) agriculture. We are writing this book to contribute to such an analysis and we are hoping to receive feedback, comments and critiques from fellow workers and comrades.

For six weeks, we worked on an organic meadow orchard company somewhere in rural East Germany, which makes apple juice and sells a few other local products. We will call it Hinterland Organics.To better understand the social context of our colleagues and the workplace, we have to get some background info.

Detour: Former-GDR-rural-area “local community”

The company is located somewhere in rural East Germany, in a region that used to be under real socialism until 1990. The takeover of former GDR infrastructure and the dismantling of all industries by West Germany had major impacts on the lives of our older colleagues, and also on the younger ones growing up in the dismantled region.

The dismantling and sell-out of former GDR industries meant that almost half (43,5%) the jobs disappeared within two years from 1989-1991. Since then, almost one quarter of the former population has migrated to West Germany, leaving behind a de-industrialised society with a disproportionate number of old people. The slashing of productive sectors went hand in hand with the dismantling of all kinds of infrastructure, like public transport, schools, hospitals, cultural, social and welfare institutions1.

We were somewhat aware of the capitalist rip-off East Germany went through. However, it was an entirely different story to hear first-hand encounters at work and in our free time rather than abstract stories from the media. For our older colleagues, it was not statistics, but their lives. They experienced loosing jobs several times, being unemployed, or having only precarious, temporary jobs. They personally had to deal with the privatisation of the state-owned housing with subsidised rents, and the privatisation and enclosure of big-scale agricultural cooperatives (called Landwirtschaftliche Produktionsgenossenschaft (LPG) in German2).

According to accounts from one of our colleagues, one LPG-coop in our area maintained 7000 hectares of land with 500 workers. Those coops cultivated the fields and did many other task too. They had their own admin offices, carpentry, metal welding and mechanical workshops on site. Also, they built houses in the area and did roadworks and in winter, they were occupied with forestry. The workers lived in the nearby villages which had everything needed: schools, grocery shops, public transport, etc.

In our older colleagues we noticed a nostalgic sentiment for the GDR-mode of organising society, with job security and decent work conditions in the agriculture coops and excellent job education and university degrees. Interestingly, the very same colleagues were full of anti-communist resentments against anything sounding too overtly left-wing. We heard endless stories about being harassed by apparatchiks for wearing blue jeans (from the black market) or listening to Western rock music. At the same time our colleagues had many anecdotes about the corruption of GDR bureaucracy and how the distribution of commodities in everyday-life was organised via unofficial personal channels – like getting bricks to renovate a house from someone who knew someone in the builders’ brigade. And our colleagues had a big disgust for so-called “Stasi brothers”, meaning people who were snitching to the GDR secret service.

For about ten years, there has been a slow but steady influx of new inhabitants to the area of our workplace. They are people that used to live in big cities, especially in West Germany, taking advantage of the comparatively cheap property prices in the East. They buy weekend houses or move to the East permanently. Property prices in the East have increased because of higher demand.

On the surface, this means that within formerly tight communities, people with very different socialisations, identities, walk of lives and attitudes now live together or at least next door to each other. This creates tensions with the ‘original inhabitants’ (a very questionable term as many of them have also only been there for one or two generations). One of our colleagues basically blamed anything bad that happened around his area on “Wessis” (people from West Germany), literally anything: Car parking offenses, litter on the ground, stolen chickens, rising property prices… In our eyes those resentments are not about geography but rather about rich yuppies, which, as furious farmworkers, we can relate to.

The topic of GDR history and post-GDR deindustrialisation with its consequences reaching until today is massive. We cannot deal with it here comprehensively by any means. Still, we find the widespread GDR nostalgic but anti-communist attitude coming from a certain structural reality worth mentioning. Especially as we have millions of fellow (migrant) workers in Europe with a Post-Eastern bloc experience of going through the dismantling of real socialist certainties and a sellout to capitalism.

Importantly, the experiences of our colleagues are not just feelings, they are about material realities. Comrades from Revoltmag speak of West German colonialism, stating the fact that the majority of leading positions in East Germany is held by Westerners3. This is confirmed by the accounts of our colleagues. One story we were told was about the new Western owner of a privatised LPG. He gave orders to the workers via the phone from his villa in West Germany, telling them when to do the harvest. The workers on site knew perfectly well that the harvest was not ready yet, as the weather was different in the West than in their region.

We experienced that our colleagues are more pragmatic in their politics and beliefs than what we know from the West. For example, someone we got to know went to a demonstration opposing an anti-vaxxers-demo. When he spotted an acquaintant he had not seen for a while in the anti-vaxx demo, he walked over for a chat. After the chat, he joined ranks again with the demonstration of his own opinion. For most politically active people we know, such pragmatism is unimaginable.

About the company

Hinterland Organics produces apple juice from their own organic apples. Beside the apple trees, the company owns pear and quince trees which are used for apple juice mixes. Additionally, there are hazelnuts, chestnuts and walnuts, and about 20 beehives for honey production. They also make dried fruits and vinegar. The owner hunts game and sells the meat via the company. Also, there are some storage crops like pumpkins, potatoes and beetroots, and over summer, they produce a few extra vegetables and lettuce on the side, to spice up the direct marketing. In winter, they prune their own standard fruit trees and they do pruning as a service for private customers.

The current owner bought the company about 7 years ago. He is a wealthy businessman who makes his living as the founder of another company in an entirely different industry. Once again, we found ourselves working for a wealthy guy who likes apples, and invests capital into meadow orchard farming (read inquiry nr. 2 for our experiences in another fruit company4). We met the owner on site only twice, and another time for an end-of-season-dinner with the whole team.

From day to day there are two operating managers, who are equal in the hierarchy and in charge of different realms of the daily business:

Manager A is in charge of all work regarding the meadow orchards, pomology, pruning, office chores like payslips and invoices, coordinating staff and helping hands for the harvest.

Manager B isin charge of technical tasks, doing machine work, coordinating the apple pressing and bottle filling plant, sometimes he was in the office too.

The business consists of a juice press and a filling plant, plus roughly 30 hectares of meadow orchards with about 3000 standard fruit trees (“Hochstammbäume”). The company’s infrastructure consists of an old shed mostly used as storage space, a renovated shed, two new tractors, an old tractor and several appliances for the tractors, like tillers, bar mowers and so on. On first sight, 30 hectares of meadow orchards plus processing facilities sounds similar to our experiences as described in inquiry nr 2, where you will also find more info on meadow orchards. But our experiences at this company were entirely different.

The apple harvest season is roughly 10 weeks long from late august until early november. The season we were there, they told us, was the biggest amount of apples they had ever processed in one season. It was about 60 tons in total. Roughly those get pressed into 36,000 liters of juice and 24 tons of remnant pomace.

During our stay, when the harvest was on full steam, we estimate that on average we pressed 8,833 kg of apples into juice per pressing day. Usually there was one pressing day per week. Sometimes twice a week. 8,833 kg of apples result into roughly 5,300 liters of juice and 3,500 kg of remnant pomace. Taking into account statistics on the current consumption levels of fruit juices. Those numbers quickly appear tiny:

The average per capita consumption of fruit juices and fruit nectars together lies at 28.5 liters in Germany. Of those are 5.6 l apple juice and 6.9 l orange juice5. So let us say the 36,000 liters of juice that were produced at Hinterland Organics in one season are very sweet, so most people will dilute with about one third of water. Which gives us an amount of 48,000 l.

48,000 l divided by the amount of annual juice consumption per capita (28,5 l) comes down to a supply sufficient for 1,684 people for one year. Assuming our apple juice is the only juice they drink.

Instead we could take into account only the 5.6 l of apples juice consumption per capita; assuming a workers insurrection takes place and we will be cut of from the global supply of oranges and other fruit: So our 48,000 l divided by 5.6 l per capita consumption results in 8.571 people drinking 5.6 l each per year. Which matter of fact is less than on pint per month. So this shows we are really moving in a very tiny artisanal niche.

The managers told us that the owner is researching ways to make the business legally independent from his person to secure the existence of the orchards beyond his own life. One option might be to transfer all meadow orchards and infrastructure of the company into a non-profit foundation. Tenant farmers could lease the place and run it the way they see fit. This way, they could operate a meadow orchard farm without having to get indebted, and they would be able to leave again, if it turns out that it is not their thing after all.

Our arrival

We arrived a day earlier to move into our accomodation, a furnished room we had rented in a family’s home. The family was recommended to us by Manager A. We were welcomed warmly and briefly met up with Manager A, who told us that she was sick and would not come to work the next day, but that Manager B would be there and would look after us.

The next morning we commuted the few kilometers to the farm. Manager Bwas completely stressed and nervous. The situation was bizarre: We just walked in and started working, without a “hello” or an introduction or anything. We were too run-over to react immediately or set boundaries. So we jumped into a 10.5 hours workday pressing apples rightaway, as the press was already set up and ready when we arrived.

One of us ended up at the conveyor belt, sorting out the bad apples from the good ones. The other one of us was directly at the press, together with Manager B. It was very loud and therefore never clear if Manager B was telling an anecdote or actually explaining something important about the work process. So of course, without a proper instruction things went wrong: apple pomace (the residue of pressed apple) splashed out of the press and all over the room. This caused even more stress and bossing around by Manager B. At the end of the day, the two of us had to clean up the press and the equipment, which again happened without an instruction, so we were very clumsy and it took ages. The pomace and juice are very sticky, and whenever one part is cleaned with a water hose, the pomace is splashed back by the water on an already clean part, and you have to start again. It felt super weird that we were left alone cleaning the press: the other colleagues had left the place in the afternoon, and Manager B was somewhere in the office. Meanwhile we did not have a clue about the work roster or the structure of the day.

The first two days were like that. On the third day Manager A was back at work. We told her that if it stayed like this we would leave. Then, Manager A talked for longer with Manager B and things got better right away. Apparently the managers are great at receiving honest feedback. From then on we were able to always ask lots of questions and to organise the work very autonomously and sometimes unsupervised. We were encouraged to just try out things and not to worry much: If something goes wrong, that is how you learn it.

The work we did

Pressing

Each week, we worked on the press for one day. Making juice out of apples works like this:

After harvest, the apples are stored in big wooden bins. A bin contains 320 – 350 kg of apples. Then, they are put in a bin tipper with a forklift, they run over a conveyor belt and through a washing machine, and into the press. At this company they have a very old-fashioned artisanal hydraulic cider press (called a Packpresse in German)6. Standing by the conveyor belt sorting the bad apples from the good ones was an easy task, usually done by one of us with an older colleague. While sorting apples, you also have to make sure the process runs smoothly: You have to keep an eye on the tap, adjust water levels in the washing machine and take care that no apples jam the machine. The heavy task was directly at the press: This was done by another one of us together with Manager B: Directly at the press it is very noisy and means a lot of heavy lifting.

On pressing days, Manager B and another colleague started at 7 a.m., to set up the pressing equipment. At 8 a.m. we arrived, we filled in the first load of apples and started running the press. The pressing process keeps four workers busy. Afterwards the cleaning takes another two hours with two to three people, and is a tricky process, as we experienced on our first day.

The freshly pressed juice runs via hoses from the press into tanks next door in the bottling plant room. Here it is stored overnight in the bottling plant. Depending on the pressing day we pressed between 4,000 and 6,600 liters stored in 1,000 liter tanks. On average, we pressed 5,300 liters of juice per pressing day, usually with one pressing day per week. 5,300 liters of apple juice means we pressed 8,833 kilos of apples, leaving behind 3,500 kilos of pomace. The pomace is taken out of the press by hand and later used as organic fertiliser on the fields. This means over the course of the day two workers carried 3,500 kilos of pomace around. On a few pressing days, we worked 10 or 11 hours with only half an hour lunch break. A few times we had an additional shorter chocolate-munching-break.

The vast majority of the pressed apples comes from the company’s own orchards. A smaller share comes from private customers and is pressed as a paid service.

Bottling

The day following the pressing, two or three people work on the semi-automatic bottling. That works like this: The juice runs from the tanks through hoses, through a pasteurizer and into the bottling machine. A gas burner heats up the juice to about 80°C in the pasteurizer. This makes the juice shelf stable for up to two years. Then, the hot juice runs through pipes into the little bottling plant. The bottling plant was very loud, so we were wearing ear plugs (our own, as they did not give us any). It was basically a task on an assembly line. One person had the easy task of standing on one end of the plant filling in the empty bottles. The other person had the heavy task, at the other end of the plant. This meant taking the hot glass bottles off the conveyor belt, then putting six bottles into one crate. The full crates (6 x full 1 liter glass bottles plus crate = about 9 kilos) are then lifted by hand and dipped into a bathtub-like container with cold soapy water. This is to insure the vacuum lids seal closely and the filled crates and bottles are clean on the outside. Afterwards, we had to lift the crates up again by hand and stack them onto a pallet. Full pallets were put away with a pallet jack7.

As long as the machine was running this was a simple job. Still, we had to be on alert as the machine sometimes makes mistakes, like failing to put the lids on the bottles or a bottle getting stuck, blocking the whole line. The aim is to keep the machine running continuously without downtime. Parallel to that, we had to keep an eye on opening and closing the different tanks on time so the pulpy fruit residue at the bottom of the juice tanks stays in the tanks instead of blocking the pasteurizer. Also, we had to get new supplies of lids, crates and bottles from the storage in periods when the machine was running smoothly.

About 98% of juice was bottled into one-litre glass bottles. Sometimes, it was filled into three-litre bag-in-box units or small 250 ml-bottles. This always disturbed the work flows and caused chaotic improvisation with additional workers and heavy lifting. Usually, the bottling days were as long as the pressing days. Later in the season, those long days were split into two shifts and we swapped with colleagues halfway through to distribute the heavy work more evenly. There was no obvious reason for this, probably one of the managers came up with it.

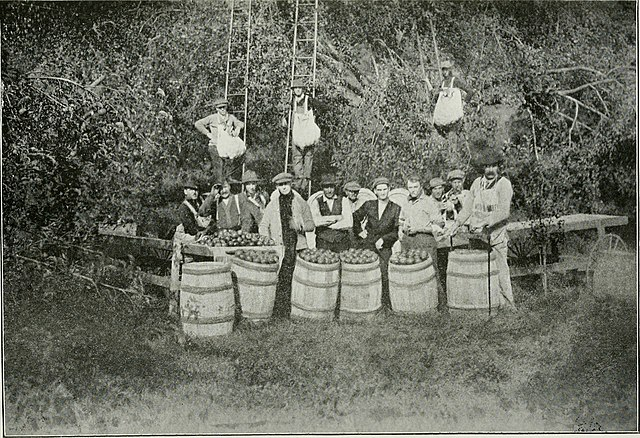

Harvesting

After pressing and bottling, the rest of the week was much easier. One or two days we spent out in the meadow orchards harvesting apples. For this, a whole lot of casual and part-time workers came in, creating a sociable atmosphere. In total, we were between 6 and 15 people on harvest days. It felt great to see the endless amounts of harvested apples by the end of the day. And it is fun to rotate the different tasks in the team: Some workers go ahead pre-collecting the apples which are lying underneath a tree. Others follow, laying plastic sheets under the trees and shaking the trees with the help of long poles, so the apples drop down from the tree. From the sheets, the dropped apples are sorted into buckets for good quality apples and compost apples. The full buckets with good quality fruit are tipped into big wooden bins, which are brought in with a tractor and a trailer.

Usually, the harvesting days took only around seven hours, including driving to and from the meadow orchards, which were sometimes a few kilometers away. The majority of the land belongs to the company and surrounds the farm immediately. A few patches of meadow orchards are rented additionally and are a few kilometers away.

Other tasks

We spent the remaining work days on-site, doing all kinds of odd jobs:

One task is labeling the juice bottles with a semi-automatic labeling machine8. First, we set up the machine. One worker stands at one end, feeding the bottles into the line. The second worker stands at the other end, taking off the labeled bottles, putting them back into crates and putting the full crates back onto pallets. So this was another assembly line task. It meant a lot of heavy lifting of juice crates. As a matter of fact, this mode of production means that every single bottle has to be taken in and out of the crate at least twice, and each 9 kilo crate is stacked up and dismantled again from pallets several times by hand. Sometimes the machine wrinkles the labels, so we had to ask Manager B for help. After a while we figured out how to adjust the mechanics ourselves. Overall, we found the labeling process very improvised.

Another improvisational highlight is the dried fruit: We started the process by clearing and cleaning a table in the big shed where everything happens. Then, we put down some chopping boards. Using a sharp slicer, and a kitchen knife to take out bad bits, we sliced the apples and put them on big trays. The full trays were loaded into an electric fruit dryer9. The dryer looked a bit like a big fridge and dried out the slices overnight. At the other fruit company we worked for, they told us they stopped producing and selling dried fruit because it was not profitable. Unfortunately, we do not have any numbers on the profitability of dried fruit at Hinterland Organics.

There were more odd tasks, like tidying and cleaning up the place, harvesting and sorting potatoes, or distributing pomace on field.

How the deal worked out for us

After the bumpy start we mostly got along well with the motley crew that were our colleagues and the managers at Hinterland Organics. Both managers were involved in all tasks and working among us, so it did not feel hierarchical most of the time.

The coordination of work was very chaotic and often last minute, which was fine with us for the season. We were not rooted in the area but simply wanted to work. However, for working long term it is annoying and we would not have been willing to accept it, as we still want to do other things in life and have reliable work rosters, which allow off-work planning.

In the end, we never worked a single regular 8 hour-work day. We had a few longer days, but most days were around 7 to 7.5 hours. The default mode is a 5-day-week. When working Saturdays, we got another day off in lieu during the week.

Effectively we worked there for six weeks, on average a 35 hours-week each. At the German minimum wage, 12€/hr gross, we made 1971€ net in total, which comes down to 1430€ net per month. The two of us subrented a furnished room in a family’s house in a nearby village which cost 300€/month. We used our car for the roughly 10 kilometre commute to work. Without any other responsibilities we managed to do a whole lot of sightseeing in the area and still managed to put several hundreds of euros in the piggy bank. Of course, this is an entirely different story for workers with families to support and housing to afford.

Except the two managers, all colleagues got minimum wage. Working full-time, 40 hours a week, with seasonal fluctuations in workload, our estimate comes to 2088€ gross = 1480€ net per month. Most farm workers in the area are paid legal minimum wage. The rises of the minimum wage in several steps up to €12 were the only pay rises many workers in the region got in years.

A motley crew of colleagues

The owner and five colleagues at Hinterland Organics were originally from East Germany. About as many had a West German background and had moved to the area within the past few years. Mostly they seemed to be driven to the country by the comparatively cheaper costs of living, escaping urban gentrification, but also because of ideas of country life homesteading.

Beside the two operating managers, there was only one other colleague working a 32-hour week all year round with seasonal peaks in work hours. Then, there were several part-time workers to do shop deliveries or odd jobs, and several more people working part-time at very irregular patterns. About seven people casually helped out on harvesting days or for odd jobs.

One of our colleagues from the area told us many interesting stories about his life. Even though he is one of the resigned people, it was interesting to us to notice he still had a clear working class attitude: He was usually relaxed about the managers’ demands. He worked at the company to earn money, nothing more or less. To get things done, he would go home and work on his own projects, like selling honey to finance his other hobbies.

This colleague had studied agricultural engineering in GDR-times and worked in a GDR-coop until it was dismantled. Since then he has been getting by doing all kinds of jobs, mostly in agriculture. He does a lot of DIY and self-sufficiency farming at home. Before working at Hinterland Organics, he had worked in a factory farm with thousands of pigs. He had to inject medicine to sick pigs and carry out dead ones every day. This was very heavy work he ended up doing manually because the animal excrements made it super slippery inside. He was appalled that the vet was very quick to hand out vast quantities of antibiotics and other medications rather than inspecting animals individually, which of course made the job easier and more profitable for the vet. Our colleague said the nightmares about dead pigs haunted him for almost two years after quitting that job.

He had also worked as a pesticide sprayer on a huge conventional farm with more than 1000 hectares. There, he drove a sprayer with a span of up to 30 metres. From his first-hand experience, he is convinced about the danger chemical pesticides pose to nature and people. He stated very clearly to us that he would never do a job like that again. He told us of a friend with lung cancer, which everyone assumed was caused by the pesticides he inhaled during farm work.

Also, he mentioned that he had several colleagues the bosses wanted to deploy as pesticide sprayers. But those workers purposely failed the sprayer licence exams that they were supposed to pass to be legally allowed to spray. So among farm workers there seems to be a strong reluctance to handle certain dangerous substances. They do it, as they are being ordered to, but the bosses giving those orders would not be willing to do it themselves. Under workers’ control, we imagine something will change there quickly. It is worth considering which consequences this has for production.

Health and safety

Health and safety conditions at Hinterland Organics were not good. In one of the sheds we had to work in a few times, there was no proper light, so we were working in the twilight. In the improvised shed where we prepared and ate our lunch, an electric cooker with a broken off-switch almost burnt a hole in one of the fridges. That could have set the whole place on fire! There were only two sets of earmuffs for the entire company. For the cleaning and the pressing, we needed proper waterproof gloves that reach up to the elbow, otherwise our sleeves got soaking wet. But there were only two pairs of these gloves and they were too big for most people. It would not have cost much money to buy these materials. In fact, it would save the company a lot of money in wasted work time: Not having proper materials, like working with gloves that are too big, takes a lot of extra time.

There were no changing rooms or proper sanitary facilities. There was one toilet on the company grounds, a compost toilet. It was clear that it had not been put there for ecological reasons but because it was the easiest option in this improvised place. We were not sure the toilet was ever cleaned in the time we were there. The cleaning of the workplace seemed to be a task that was not taken seriously as work (apart from cleaning the rooms where we pressed and filled juice – which might be inspected by health authorities unannounced). There was one place where we could wash our hands, only with cold water. This was outside, at least 20 metres away from the toilet, and did not have a sewage system, only a bucket underneath. The towel to dry our hands was only changed about once every two weeks, and several times that was done by one of us.

There were (fruit) flies everywhere and there was no proper strategy to deal with them. The vinegar traps only worked partially.

One of us used the forklift and the tractor for work with about thirty seconds of instructions for each vehicle, as I had driven similar vehicles before. It went fine and I quickly gained confidence in handling the vehicles. However, I was grateful I had had a proper instruction to it in previous workplaces.

Work attitude

Hinterland Organics is neither a family business nor the typical ‘alternative project’. There was definitely less self-exploitation than in the family business we worked for. Although the managers still seemed constantly overworked, they also regularly took time off. And importantly, none of the employees or managers regarded the business or their job as their identity, which was very different in the eco village, the family farm and the CSA project we worked in.

Most employees did not care much about doing a good job, which sometimes produced a careless working atmosphere, with people holding back suggestions to improve the work progress, or doing work that was clearly useless or stupidly organised. Of course, we understand this attitude. It is a way to not let the wage work take over your personal headspace, and to leave wage work at work and not take it home. It was just a job for them, which meant making sure to knock off on time and to get time off in lieu for all the overtime collected. However, sometimes this attitude also means you cannot learn to do your job properly (to us, that also means learning to be efficient).

As you can see from the picture painted in the section on health and safety, the place was highly improvised, which also had its advantages. For example, it was no problem to get an informal agreement about being employed a bit longer on paper to avoid getting in trouble with the dole office. Also, we were allowed to practice working with the forklift and the tractor.

There was no conscious leadership or corporate culture in this place. The managers often seemed stressed and overworked. As far as we could observe, no one bothered about management strategies. The administration was very messy. For example, for one month we were accidentally paid twice, which we then had to transfer back. And it took weeks to get our payslips sorted correctly.

Conspiracy theories

One thing we found very tricky was the conspiracy theories we had to listen to during work or during breaks. As described above, we had a few colleagues from an ‘alternative’ background who escaped to the East of Germany to follow a romantic dream to be self-sufficient. Two of them were anti-vaxxers with several conspiracy theories about everything. They had had to stop doing their jobs in the health sector because they did not want to get vaccinated, and were now doing odd jobs at Hinterland Organics. Then there were our colleagues who grew up in the region, who also had all sorts of conspiracy theories.

They did not have faith in anything or anyone: not the Left, not the government, not political organising. At least one of them mentioned they were considering going to a corona deniers’ demo organised with people from the far right.

There was a bitter, resigned mood: “Everything sucks, but what can we do about it.” This was expressed in at times very bizarre conversations mixing up several topics: Climate change denialism, concerns about energy shortage scenarios, suspicion against Ukrainian refugees, disbelief in the official stats on the corona pandemic, and so on. Sometimes a colleague said one thing and the exact opposite two sentences later.

For us it was very frustrating to have to listen to this. Sometimes we did not reply, as we were too busy working to think of a reply. Other times we tried to carefully challenge their ideas, but we did not go for an outright confrontation. As we were only there for six weeks, we could not build up the long-term trust needed to have fruitful political discussions.

Some conclusions

We really enjoyed being in an environment very different to the usual organic alternative bubble. It was hilarious to be offered cake for lunch as the only vegetarian option. It was refreshing to work in a place that has a direct, honest and sometimes rough language. There was no back-stabbing or false middle-class politeness as we encountered in the be-the-change-you-want-to-see-in-the-world- eco village (See chapter 1: https://www.angryworkers.org/2023/01/29/farmworker-fury-inquiries-about-organic-agriculture/).

We experienced little leadership by the management of the company, and the managers were not offered help in learning to coordinate the work better. At its best, this lack of leadership resulted in an an openness to try out new tasks and to learn on the job. At its worst, it led to chaos, last-minute decisions and an inability to plan ahead.

Conspiracy theories seem to be a huge obstacle to workplace organising. You never know what crazy bullshit the conspiracy theorists come up with next, and you can never win the argument. Moreover, conspiracy theories drive people away from a clear class understanding. In stead of seeing the world as divided into classes, conspiracy theories are often based on the idea that a handful of people control the world. This makes it hard to focus on the division between boss and workers. Also, it drives a wedge between workers. As a small group of people who were only at this company for six weeks, we found it very hard to come up with a strategy to deal with the conspiracy theories at work. We are curious if anyone has ideas about this.

Our time at Hinterland Organics also made us think of the role of alternative yuppies, as we saw these people come in from the big city to get cheap houses in the countryside. As described above, there was a huge resentment in the local community towards such people, but we also met locals who felt it was good to have young people moving into the deserted villages, especially if they don’t just live easy lives in their weekend houses, but do useful things in the community (join the volunteer fire brigade etc.).

What this work place taught us more than others is that as revolutionaries, we have to listen to the concerns of working people, also the ones that start with “You are not allowed to say this anymore, but …”. We have to practice to truly listen without judging and then to respectfully challenge reactionary beliefs. The good news is that we can start practicing this today with our comrades, family members and friends. Although some (self-proclaimed radical) leftists and liberals pretend that East Germany is full of nazis, we noticed that there are lots of nuances in people’s attitudes. Like our colleagues who were prone to believe conspiracist right-wing narratives and at the same time happily work together with an Afghan colleague with a refugee biography.

At this company we realised that a starting point for a conversation about working conditions could be to talk about toxic substances and chemical pesticides. It is in all workers’ interests to stay healthy and not to have to work with toxic substances such as pesticides and fungicides, and it will be a common reference point to land workers around the globe.

Working class organising potentials

It was definitely interesting to work at Hinterland Organics. The place is looking for workers willing to learn and to commit more long term. Practical skills that can be learnt are for example growing fruit without pesticides, pruning standard fruit trees, handling different machinery in the pressing and bottling, and also driving vehicles like tractors and forklifts. We just had to ask once to be allowed to practice.

However, we estimate the potential for workplace organising or even a workers’ takeover to be close to zero. First of all, the owner is not financially reliant on the workplace as he makes enough money in his first company (which has nothing to do with this apple business). So if workers ever get too rough and rowdy, he could just close down the whole place without going bankrupt. (Although this would come at a high loss of social capital in the local “community”.) Secondly, we found class distinctions at this company not super clear. The managers worked alongside the workers. When the boss showed up (twice in the six weeks we were there) he did so too. Additionally, we think the huge resentment and bitterness in the area will complicate any workplace organising. And last but not least, there are very few job opportunities in the area, making it a huge risk for people to join in any workplace organising.

This is the third published chapter from our forthcoming book. To be continued soon.

We are keen to hear your criticisms and to get to know fellow comrades in land- and farmwork and

a willing publisher: farmworkerfury@riseup.net.

1For a more comprehensive overview of the history of the GDR with further references we recommend the following articles by comrades from revoltmag (in German): https://revoltmag.org/articles/warum-eine-ostdeutsche-linke/ , https://revoltmag.org/articles/deutsche-demokratische-republik-kurz-ddr-teil-1/ and https://revoltmag.org/articles/deutsche-demokratische-republik-kurz-ddr-teil-2/ all numbers in this section we quoted from there.

2More on LPG here: https://de.wikipedia.org/wiki/Landwirtschaftliche_Produktionsgenossenschaft and in English: https://en.wikipedia.org/wiki/Landwirtschaftliche_Produktionsgenossenschaft

3For a more comprehensive overview with further references we recommend those articles in German by comrades form revoltmag: https://revoltmag.org/articles/warum-eine-ostdeutsche-linke/ , https://revoltmag.org/articles/deutsche-demokratische-republik-kurz-ddr-teil-1/ and https://revoltmag.org/articles/deutsche-demokratische-republik-kurz-ddr-teil-2/ all numbers in this section we quoted from there.

4 https://www.angryworkers.org/2023/03/02/farmworker-fury-inquiries-about-organic-agriculture-the-family-business-chapter-2/

5https://de.statista.com/statistik/daten/studie/167145/umfrage/pro-kopf-verbrauch-von-apfelsaft-in-deutschland-seit-2002/ and https://www.fruchtsaft.de/branche/daten-und-fakten/ both accessed on 14th of March 2023

6 here is a picture of such an appliance: https://en.wikipedia.org/wiki/File:Bucher_Cider_press.JPG

7 https://en.wikipedia.org/wiki/Pallet_jack

8 Kind of like this one https://german.bottle-labelingmachine.com/photo/ps23755802-ss304_auto_bottle_sticker_labeling_machine_with_paper_or_plastic_label.jpg

9 Kind of like this one https://www.armbruster-berghaupten.de/images/pictures/wrh-100t-links.jpg